Making 16-T dipoles is a challenge to both magnet and conductor technology. This program element’s role is twofold: procurement of “workhorse” conductors to support the present-day magnet program, and anticipation of future needs, including both high- and low-temperature superconductor wires and cables. Research emphasizes the present industrially produced cuprate high temperature superconductors, Bi-2212 and ReBCO, that can be cabled. Our CPRD efforts will strive to maintain a carefully balanced portfolio, while also emphasizing conductor manufacturing. Key elements of CPRD include definition of achievable goals and milestones for:

- Determining the performance limits of Nb3Sn and high-temperature superconductor (HTS) conductors.

- Understanding uniformity and reliability, especially of HTS conductors.

- Understanding of future conductor scalability and cost.

- Evaluating factors critical for eventual worldwide capacity ramp-up for future projects so as to minimize start-up costs and allow more competition.

Click for larger version |

Click for larger version |

||

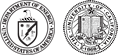

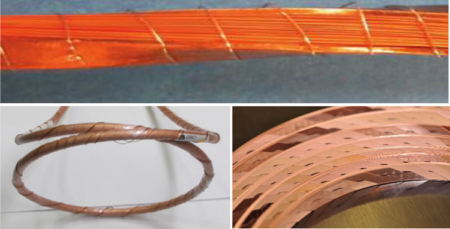

| Top: Twisted tape-stack cable (courtesy of Dr. Makoto Takayasu of Massachusetts Institute of Technology). Above left: ReBCO conductor-on-round-core (CORC) cable (courtesy of Dr. Danko van der Laan of Advanced Conductor Technologies LLC). Above right: ReBCO Roebel cable made from the Bruker ReBCO tapes for the EuCARD2 project (courtesy of Dr. Anna Kario of Karlsruhe Institute of Technology). | Right: Strands of three kinds of wires made into the “Rutherford-style” keystoned cable generally used in accelerator magnets. Above, top to bottom: Cross sections of keystoned 40-strand (0.7 mm) Nb3Sn Rutherford cable with an 11 mm wide and 25 mm thick stainless steel core; 27-strand (1 mm) Nb3Al rectangular cable; 25-strand (0.8 mm) Bi-2212 rectangular cable. (All images courtesy Fermilab.) |

||

To Learn More…

Click here to get detailed information on these topics and meet the management lead for this program element.