Breakthroughs in magnet performance, particularly in training and operating margin requirements, will require further understanding and control of the underlying physics mechanisms. Energy deposition that initiates quenches, resulting in training or sub-par magnet performance, can emanate from a variety of sources, resulting in a “disturbance spectrum.” Well-defined experiments designed to identify and “fingerprint” the sources, and to evaluate technology alternatives that minimize the amplitude of such disturbances, are critical to addressing the goals of the program. This magnet science component of the program leverages developments in modeling, materials, and diagnostics that are critical to advancing magnet technology and serve as a core element of the MDP.

Directions and Deliverables

We are pursuing a broad technology development program designed to focus on specific topics related to the Driving Questions. This activity is a combination of science-driven modeling and simulation studies benchmarked against dedicated, focused tests with limited scope. These tests are relatively low cost with fast turnaround, where “fast” is defined as less than 3 months. Essentially the activity is a reformulation of our successful sub-scale program where speed, simplicity and low cost are the primary criteria. The scope of a given study topic would easily fit the available infrastructure and capabilities of a small university group or industrial partnership, thereby providing opportunities for a larger, more cost-effective program. The program will also provide guidance for Small Business Innovation Research (SBIR) proposals.

Technology development and training studies using subscale and model magnets

Subscale models designed to provide rapid, cost-effective turnaround will support Nb3Sn and HTS magnet developments and address the driving questions. These subscale models serve as the initial magnet testbeds for exploitation of improvements in materials and diagnostic techniques.1

Development of new capabilities

To develop new capabilities (e.g., insert-testing infrastructure and techniques, expanded facility resources and availability), the MDP will integrate test groups at participating institutions for efficiency, increasing intellectual critical mass, improving capabilities and providing adequate accessibility. Integration of the US magnet and materials programs will result in more effective use of existing facilities but there will be a need for upgrades to accommodate the requirements for the next generation of high performance magnets. New capabilities for testing novel magnet configurations are essential to provide insight into magnet behavior and feedback for magnet improvements. Subscale and model magnets need to be tested with a spectrum of diagnostics and flexible test schemes, and these capabilities must be available for rapid turnaround. Further into the program, facilities will need to be upgraded to allow testing of hybrid (low plus high temperature superconductor) magnet systems.

Investigation of new materials (insulation, impregnation and structural materials, etc).

The primary sources of magnet training emanate from materials and material interfaces, in particular the insulation, impregnation, and neighboring structural materials. There is ample evidence that training behavior derived from these sources can be affected by the support structure design and pre-stress configuration. This is a ripe area to explore for significant improvements in magnet performance: examples include improvements in insulation materials (e.g., quartz or ceramic fibers vs. the traditional S-or E-glass fibers); new techniques that can eliminate insulation sizing completely, or clean the sizing from wound magnets; surface treatments that can significantly improve epoxy adhesion; improvements in the epoxies themselves to enhance toughness; and superconductor and structural material chemical compatibility. These areas can be explored with low-cost, dedicated laboratory experiments prior to testing in subscale magnets, and are ideal for collaboration with universities and industry (e.g., SBIR).

Further development of analysis tools, quench detection and protection techniques, and diagnostics

Analysis tools have progressed significantly and when coupled with well-instrumented subscale and model magnet tests can provide essential understanding of magnet behavior and hence directly address the driving questions for the program. New diagnostics can be designed to provide critical feedback in areas where analysis shows high magnet performance sensitivity. Furthermore, the potential exists to “fingerprint” the disturbance spectrum sources to provide direct feedback on the mechanism of training.

Full 3D magnetic and mechanical modeling of complete magnet systems can now be performed, including all interface considerations; concepts can be iterated and optimized, i.e., virtually prototyped, prior to freezing a design and procuring hardware. First implementation of finite-element analysis (FEA) software on parallel clusters has shown order-of-magnitude reduction in simulation time; we envision similar enhancements over the next couple of years, which will enable new optimization approaches to be applied to magnet design. Similarly, magnet protection mod- els can address a breadth of spatial and temporal scales, from quench initiation and early propagation to full circuit modeling including coupled magnet, power supply and dump resistor behavior. Development of reliable stress/strain gauges with large temperature and field ranges are important for understanding magnet behavior and benchmarking magnet design and simulation codes. Sub-scale magnets will provide a cost-effective method for studying methods of correcting and compensating coil magnetization effects.

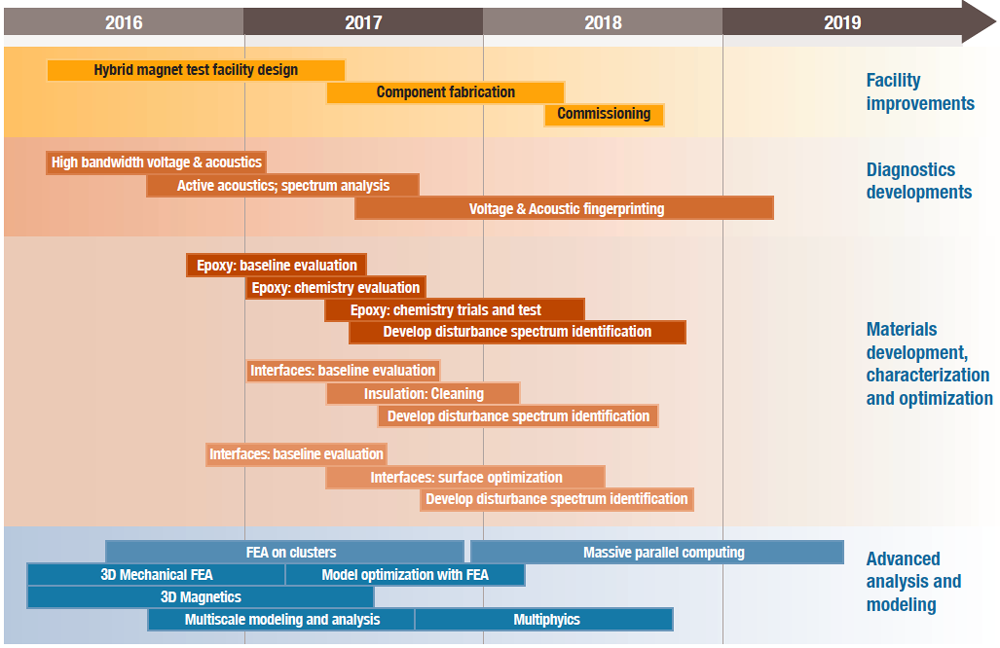

Design comparison and cost analysis to guide program direction. Historical preferences for specific magnet design concepts are common in the high-field magnet community. Designs need to be subjected to objective, quantitative scrutiny to identify relative advantages and disadvantages and to guide the program towards the most effective and efficient solutions. A timeline for major milestones for the technology development program is shown below.

Foundational-technologies development and milestones

Meet the leads

This aspect of our work is organized into four sub-areas, each with one representative from each DOE laboratory to ensure that all available expertise and capabilities can be brought to bear.

| Technology Sub-Area | LBNL representative | Fermilab representative | ||

| Modeling and simulation | Diego Arbelaez | Vadim Kashikhin | ||

| Training and diagnostics | Maxim Martchevsky | Stoyan Stoynev | ||

| Instrumentation and quench protection | Emmanuele Ravaioli | Thomas Strauss | ||

| Material studies – superconductor and structural materials properties |

Ian Pong | Thomas Strauss | ||

References

1 S. Caspi, L. Chiesa, M. Coccoli, D.R. Dietderich, S.A. Gourlay, R. Hafalia, A.F. Lietzke, J.W. O’Neill, G. Sabbi, R.M. Scanlan, “An Approach for Faster High Field Magnet Technology Development,” IEEE Transactions on Applied Superconductivity 13, 2 (15 July 2003), pp. 1258-1261.